Catalog

-

1, Summary

-

2, Application rang

-

3, Product structure composition

-

4, Operating environment

-

5, Product function and introduction

-

6, Installation and commissioning

-

7, How to operate the descaling machine

-

8, Fault analysis and troubleshooting

-

9, Safety protection device and accident handling

-

10, Transportation

-

11, Maintenance

-

12, Supply scope

1, Summary

Hydraulic Descaling System is adopted high pressure water principle for removing the oxidized layer of hot forgings. Hi-pressure descaling principle was adopted long time ago, but its cost is very high, and its operation type is manual, its pump lifespan is short, especially in winter.Litai Corporation invented Hydraulic Descaling System, It has passed the test of the market for five years, Obtained 6 national practical, appearance double patents, professional removal and collection of forgings oxidized layer, Help the forging enterprises to solve the defects of oxidation and other problems.At present, the appearance of the descaling machine in the market all comes from our patent structure.Our company has professional R & D personnel, keep forging ahead, continue to improve the descaling machine, now has been updated to the tenth generation of products. Till now, Our descaling machine has been exported to Japan, Indonesia, India etc countries, It has won international unanimous praise.

The products produced by Litai descaling machine are approved by foreign TOP 50 enterprises and Third party metallographic organization inspection.

2, Application rang

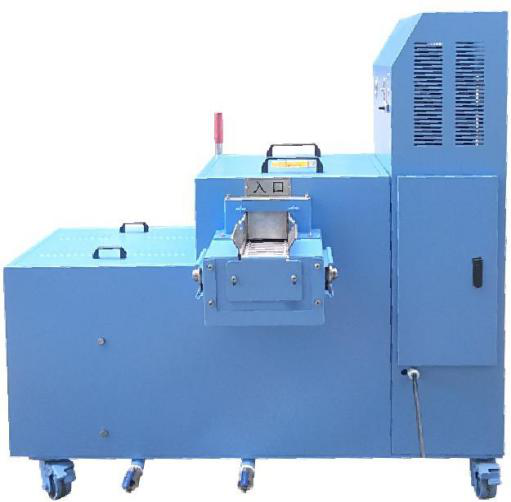

LTG-120-20 descaling machine is Suitable for cleaning round rods with diameters of 55~120mm, or after pre-forming 220*120mm(W×H), It is not applicable to other dimension parts. If you need higher requirements, you can buy our other model of descaling machine, or customized.

3, Product structure composition

4, Operating environment

Environment temperature:-10℃~50℃

(When the temperature is below zero, take care to prevent water from freezing)

Relative humidity:0~95% (non-condensing)

Environment: No combustible dust

Atmospheric pressure: NPT(normal pressure and temperature)

Cooling type: Nature cooling

5, Product function and introduction

- Automatic water inlet function: Connect the water pipe to the automatic water inlet interface below the machine to realize automatic water addition without frequent water addition.

- Main and auxiliary water tank drain valves: To facilitate the maintenance of equipment, clean the inside of the tank of the descaling machine

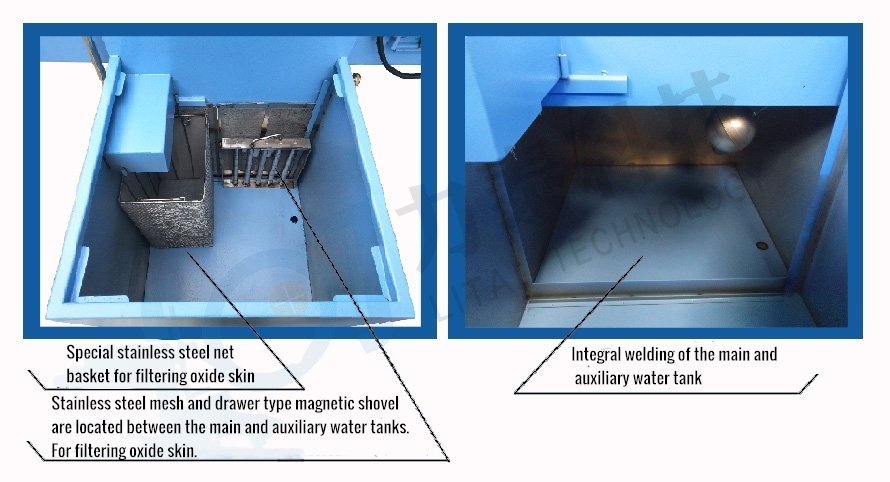

- Drawer type magnetic shovel/magnetic grate: It can easily clean fine oxidized powder in the water tank and improve the lifespan of the descaler.

- Pressure gage: Real-time check the running time pressure of the descaling unit, monitor the running state of the descaling machine, and troubleshoot the running fault.

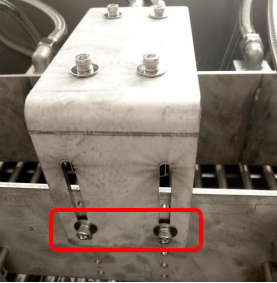

- External bearing: Easy to lubricate the bearings during regular maintenance and improve the lifespan of the hydraulic descaling system.

- Adjustable bearing: To solve the problem of mechanical stretching looseness after the chain has been used for a long time.

- Pump control switch: Independently control the start and stop of the pump, which can also be used as the transmission chain while no need descaling.

- Motor control switch: the transmission speed of the transmission chain can be flexibly adjusted according to the actual needs of production

The main parameters of LTG-120-20 Hydraulic Descaling System

6, Installation and commissioning

6.1 Power cord connection

Figure 1

L1, L2, and L3 are 3 Live Wires as per fig.4, PE wire is Each Wire, N is Naught Wire(Announcements: Five wires must be connected completely, preventing phase default. If the connection is not complete, the consequences have nothing to do with our company, resulting in damage to the circuit motor. The cost of replacement parts shall be borne by the buyer)

6.2 Pay attention to the positive and negative rotation of the motor during connection

Figure 2

Then, start the machine and close it at once, Observe the MARK(Fig.5) at the top of the pump, Checking whether the pump vane rotates according to the direction shown on the MARK(Fig.5), If its rotating direction is the same as the MARK, indicating a successful connection.(It can be turned manually before starting the machine)

Otherwise, Exchange the position among any two of the three live wires(L 1, L 2, L 3), Check whether the vane rotation direction is right or not again Until the correct motor rotating direction is attempted(Do not reverse, idle, or start without water)

7, How to operate the descaling machine

7.1 ON and OFF

7.1.1 Press the pump ON and OFF button, The button lamp lights up and the pump starts normally.Press the button again,Button lamp off, pump off.

7.1.2 Press the chain ON and Off button, The button lamp lights up and the chain starts normally. Press the button again, Button lamp off, chain off.

7.1.3 Chain button ON, Rotate the chain speed control button to adjust the chain transmission speed in real-time.

7.1.4 If necessary, Under the guidance of our technicians, we can modify the parameter setting of the frequency converter to adjust the highest and lowest speed.

7.2 Pump pressure observation

The pressure of the LTG-80-20 and LTG-120-20 descaling machine is around 1.6-1.9 Mpa, before and after a little difference, are normal pressure

7.3 Pump attention

7.31 Before starting up, the pump must be filled with water and exhaust by the exhaust hole(Figure 5)

7.3.2 If the pressure gauge is shaking, indicating that there is air in the pump, open the pump exhaust valve in time to discharge air

7.3.3 If there is abnormal sound in the pump, stop the motor work immediately, check whether the pump core is blocked by foreign matter into the vane path, insufficient water in the pump will also cause noise, which can be solved by empting and adding water.

7.3.4 Pump mechanical seal for wear parts under long-term work, should pay attention to timely replacement and maintenance.

7.4 Suitable range adjustment of the work piece

If the product height is too high, the internal nozzle of the equipment should be adjusted. Adjust the top nozzle to 30MM higher than the product according to the height of the customer’s product(For example, if the height of workpiece is 30mm, then the height between the nozzle and chain should be 60MM). Adjusting method: Loosen the four screws of the L part as shown in FIG. 6 and slide the U-groove up and down to adjust the position of the upper nozzle.

8, Fault analysis and troubleshooting

8.1 Fault:The workpiece is not cleaned thoroughly, the pressure of the pressure gauge is too high

Check: Whether the nozzle is blocked

8.2 Fault: The workpiece is not cleaned thoroughly, the pressure of the pressure gauge is too low

Check: Whether the water pump inlet is blocked, whether the equipment pipeline leakage phenomenon, whether the nozzle wear

8.3 Fault: The pressure gauge has no pressure after the pump is started

Check: Whether the pump wiring is correct and whether the pump is reversed

9, Safety protection device and accident handling:

9.1 The system shall be reliably grounded

9.2 The equipment is placed on the flat ground and the casters are in the braking state

9.3 When the transmission chain is running, do not touch it directly with your hands to prevent it from being pinched

9.4 Ensure that the power supply and the power line are allowed to exceed 6KW

10, Transportation:

10.1 The Wooden Case outer size is 1800*1400*1800.Supply Scope:1 Main desccaling machine,1 drawer type magnetic shovel, 1 filtering net bucket, 1 magnet grate, 1 set of heat insulating gloves, 1 set of internal hexagonal wrench, 1 file folder, 4 nozzles, packing list, 1 operation Menu, Electrical diagram, Frequency converter operation Manual, Quality Certificate

10.2 Matters needing Attention in Transportation: The lifting hole of the cleaning machine is not designed for lifting, only forklift can be used, it should be noted that the center of gravity is on the side of the water pump when the descaling machine without water

10.3 After placement, attention should be paid to brake the four casters to prevent the equipment from moving due to uneven ground, tilt and other reasons.

10.4 Note for storage: when the equipment is not in use for a long time, the water tank should be cleaned and water and other impurities discharged.

11, Maintenance

The descaling machine equipped with 1 net bucket, 1 magnetic shovel, 1 magnetic grate, They effectively collect the removed oxide skin and purify the water in the tank for recycling use.

11.1 According to the amount of oxide skin from the customer, the collected oxide skin must be poured out regularly, the bolt can be pulled out of the net basket, and then the net basket is put into the box and the bolt is inserted, so that it can be recycled for a long time.

11.2 In order to collect fine oxide scale more thoroughly and reduce the possibility of oxide scale entering the pump, the auxiliary water tank is equipped with magnetic grate.

11.3 Equipped with magnetic shovel, can filter out fine oxide scale in time during use

11.4 The auxiliary water tank has a drainage valve, which can be cleaned once a week. Just open the ball valve and flush the inner oxide skin. If it is not convenient to drain the water in the factory, you can connect the water pipe to drain the water by yourself

11.5 Drainage valve of the main water tank: the water in the main water tank can be replaced once a month. The ball valve can be opened and then flushed into the main water tank through the outlet of the filter screen of the secondary water tank.

11.6 After the equipment has been in operation for more than half a year, the worn nozzle should be timely checked and replaced.

Our company has a professional after-sales team and guidance team, when you have any problems with the equipment, or have any doubts, you can contact our sales staff, they will arrange after-sales engineers to answer for you.

12, Supply scope